Our process.

Sustainable design.

We draw a lot of inspiration from nature, so we take extra care to make sure our products are brought to life sustainably – from the idea to the last stage of the production process, packing, and shipping. We use natural and responsibly sourced materials. We create well thought-out designs, and we repeatedly test their functionality so that the end product is perfectly suited to your needs.

Idea

The creative process begins with a general idea. At this stage, our objective is to determine the most pressing user needs so that Oakywood products provide answers to real and current workspace organization challenges. Apart from that, we keep a close eye on technological and industry trends to help us tailor our products to market demands.

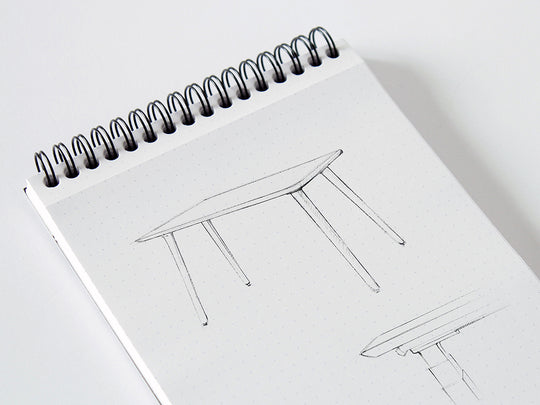

Design

Having established the initial concept, it’s time to design the products. Starting with some sketches, we try to generate as many solutions to the issue at hand as possible. Even at this early stage, we sometimes make a simple prototype or a digital 3D model which allows us to test its functionality and validity. We do our best to ensure our designs seamlessly join aesthetics with functionality.

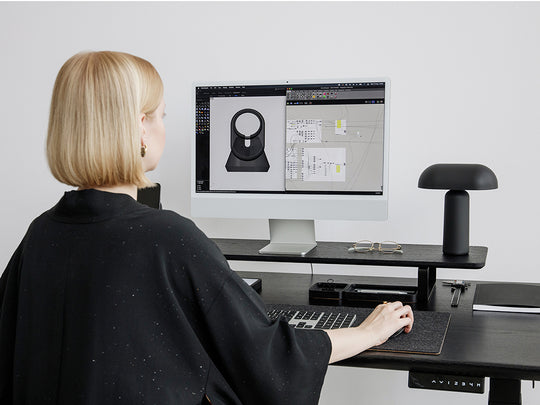

3D modeling

The next stage involves spatial modeling using the Rhinoceros 3D and Grasshopper 3D software. Through this, we are able to create parametric models based on an already prepared algorithm.

This allows us to make quick changes and iteratively prototype them – work optimization is, therefore, something we practice every day. It is worth mentioning that using tools like Grasshopper 3D in industrial design is not widely practiced – Magdalena, our Head of Design, not only uses innovative methods in her work, she knows them inside out.

Visualizations

A raw 3D model is not enough for us to assess the presentation of our product concept, so the next step is creating a photorealistic visualization. This takes into account the item’s color, texture, materials, scale, and other parameters to help imagine our product in the real world. Visualizations give us the ability to tweak the design before the prototyping stage.

Prototype

Our own, technologically advanced machine park gives us access to prototypes ready to be tested for their usability and functionality. First, we quickly prototype new products using their 3D models, the CNC technology, and our key element – wood. In case any problems arise, we introduce the fixes and manufacture new prototypes – this goes on until we obtain a thoroughly satisfactory result.

The final phase of iterative prototyping is making a prototype of each element of the final product. Through this, we can adjust the design to a particular production technology and choose the most fitting finish. Once the final prototypes are approved, we prepare the project paperwork and move on to our next step in this process – the production.

Production

The production process consists of several smaller stages which differ depending on the kind of product being made. One common feature of all our products is that each of them is developed and refined by qualified craftsmen. The wooden elements are made by lumber processing, CNC, or numerically controlled machines. Some parts are also processed manually – this usually includes shaping, sanding, and oiling. The years we’ve spent working with wood helped us develop our own unique, high-quality methods of wood treatment.

In the 5 years we’ve been operating, we managed to enhance our machine park threefold which allows us to control all stages of production: from design, through prototyping, to manufacturing the end product. This means we are able to focus on the finest details and make sure we provide you with solutions to best suit your expectations.

Constantly developing and growing our product portfolio does not affect our commitment to sustainable production – quite the contrary. Our most important values are still quality, durability, and functionality. Our Tatra workshop continuously expands, and we continue to employ qualified craftsmen, and work with local subcontractors to support our regional economy and reduce our carbon footprint.